Rechargeable Special Batteries: Low - Temperature LiPo battery and Ultra - Thin Curved battery Solutions

Rechargeable Special Batteries: Low - Temperature LiPo battery and Ultra - Thin Curved battery Solutions

Introduction

In the ever - evolving landscape of technology, the demand for advanced power sources that can meet the unique requirements of various applications is on the rise. Rechargeable special batteries, including low - temperature LiPo batteries, ultra - thin batteries, and curved batteries, have emerged as key players in addressing these challenges. These batteries offer unique performance characteristics, lightweight designs, and flexible form factors, making them suitable for a wide range of industries, from consumer electronics to aerospace and medical devices. This article will delve into the performance, materials, design features, and applications of these innovative rechargeable special batteries.

Low - Temperature LiPo battery and Lithium Polymer Batteries

Performance at Extreme Cold

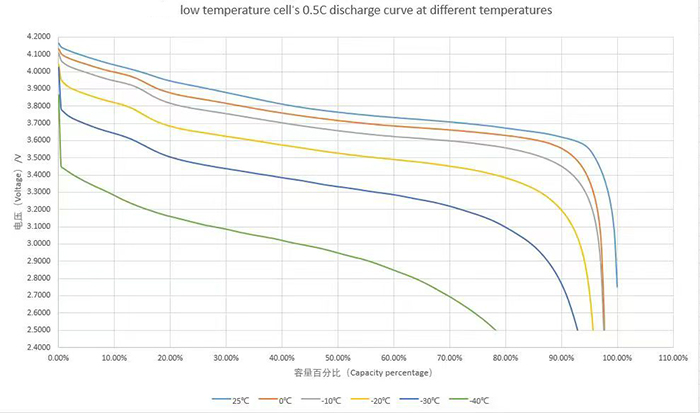

One of the most remarkable features of low - temperature LiPo and lithium polymer batteries is their ability to perform exceptionally well in extremely cold environments. At - 40℃, these batteries can maintain a discharge capacity greater than 90% of their rated capacity. This is a significant advantage over traditional batteries, which often experience a sharp decline in performance at low temperatures.

In cold - weather applications such as polar expeditions, winter sports equipment, and outdoor surveillance systems in cold regions, reliable power is crucial. Traditional batteries may fail to provide sufficient power or may even stop working altogether in such extreme conditions. Low - temperature LiPo and lithium polymer batteries, however, ensure that devices continue to function as intended, allowing users to carry out their tasks without interruption. For example, in scientific research conducted in Antarctica, where temperatures can drop as low as - 80℃, low - temperature batteries are used to power various monitoring and communication devices, enabling researchers to gather valuable data and stay in touch with the outside world.

Lightweight Design

These batteries come in a range of sizes, with weights varying from 5g to 90g depending on the specific dimensions. The lightweight nature of low - temperature LiPo and lithium polymer batteries is a major advantage, especially in applications where weight is a critical factor. In portable electronic devices such as handheld GPS units, emergency beacons, and cold - weather cameras, a light battery reduces the overall weight of the device, making it more comfortable for users to carry and use for extended periods.

In the aerospace industry, where every gram counts, low - temperature batteries are used in satellites and unmanned aerial vehicles (UAVs) that operate in cold space environments or in high - altitude regions. The lightweight design of these batteries helps to improve the fuel efficiency of the aircraft or spacecraft and increase their payload capacity.

Materials for Low - Temperature Adaptability

The excellent low - temperature performance of these batteries is achieved through the use of low - temperature adaptive cathode and anode materials. These materials are specially engineered to maintain their electrochemical activity at low temperatures. The cathode material is designed to facilitate the efficient transfer of lithium ions during the discharge process, even in cold conditions. It has a high surface area and a well - defined structure that allows for rapid ion diffusion, ensuring a high discharge rate.

The anode material, on the other hand, is optimized to minimize the formation of solid - electrolyte interphase (SEI) layers at low temperatures. The SEI layer can increase the internal resistance of the battery and reduce its performance. By using low - temperature adaptive anode materials, the growth of the SEI layer is suppressed, allowing for smooth lithium - ion insertion and extraction. Additionally, the electrolyte used in these batteries is formulated to have a low freezing point and high ionic conductivity at low temperatures, further enhancing the battery's performance in cold environments.

Ultra - Thin Special - Shaped Lithium Batteries

Ultra - Thin Profile

Ultra - thin special - shaped lithium batteries are characterized by their extremely thin thickness, with a minimum thickness of 0.5mm. This ultra - thin design makes them ideal for applications where space is extremely limited. In wearable devices such as smartwatches, fitness bands, and smart glasses, a thin battery allows for a more compact and streamlined device design. Users can wear these devices comfortably without feeling any bulkiness.

In medical implants, where the available space inside the body is minimal, ultra - thin batteries are essential. They can be integrated into small - scale medical devices such as pacemakers, neural stimulators, and drug - delivery systems, providing a reliable power source without causing discomfort to the patient.

Lightweight Construction

The weight of ultra - thin special - shaped lithium batteries varies from 0.54g to 6g depending on the size. This lightweight construction is a result of advanced manufacturing techniques and the use of lightweight materials. The lightweight nature of these batteries is particularly important in applications where weight is a critical factor, such as in aerospace and military applications.

In micro - UAVs used for surveillance and reconnaissance missions, a light battery allows the UAV to fly for longer periods and carry more payload. In the military, lightweight batteries are used in portable communication devices, night - vision goggles, and other equipment, improving the mobility and effectiveness of soldiers on the battlefield.

Flexible Design

One of the most unique features of ultra - thin special - shaped lithium batteries is their flexible design. The shape of these batteries can be curved, allowing them to conform to the shape of the device they are powering. This flexibility opens up new design possibilities for manufacturers, enabling them to create more innovative and ergonomic products.

In flexible electronics, such as curved smartphones, foldable tablets, and wearable displays, ultra - thin curved batteries can be integrated seamlessly into the device's structure. They can bend and flex along with the device without compromising their performance or safety. This flexibility also allows for better space utilization within the device, as the battery can be placed in non - traditional locations.

Applications of Rechargeable Special Batteries

Consumer Electronics

In the consumer electronics market, rechargeable special batteries are in high demand. Low - temperature LiPo batteries are used in outdoor sports equipment such as ski goggles with built - in displays, cold - weather action cameras, and portable power banks for winter camping. These batteries ensure that the devices can operate reliably in cold weather conditions, allowing users to capture and share their adventures.

Ultra - thin special - shaped lithium batteries are widely used in wearable devices. Smartwatches and fitness bands rely on these batteries to provide long - lasting power in a compact form factor. The flexible design of the batteries also allows for the development of new types of wearable devices, such as smart clothing and flexible patches that can monitor health parameters.

Medical Devices

Medical devices often have strict requirements for power sources in terms of size, weight, and reliability. Low - temperature batteries are used in medical equipment that may be exposed to cold environments, such as portable ultrasound machines used in emergency medical services in cold regions. They ensure that the equipment can function properly even in adverse weather conditions.

Ultra - thin special - shaped lithium batteries are essential for medical implants. Their small size and lightweight construction allow for minimally invasive implantation procedures, reducing patient discomfort and recovery time. These batteries provide a long - lasting and reliable power source for life - saving medical devices, improving the quality of life for patients.

Aerospace and Defense

In the aerospace industry, rechargeable special batteries are used in satellites, spacecraft, and UAVs. Low - temperature batteries are crucial for spacecraft that operate in cold space environments, providing power for various scientific instruments and communication systems. Ultra - thin batteries are used in micro - satellites and small - scale spacecraft, where space and weight are at a premium.

In the military, these batteries are used in portable communication devices, night - vision equipment, and unmanned ground vehicles. The low - temperature performance of the batteries ensures that they can operate in cold battlefield conditions, while the flexible and ultra - thin designs allow for better integration into military gear and equipment.

Industrial and Automotive

In the industrial sector, rechargeable special batteries are used in sensors and monitoring devices deployed in cold storage facilities, oil and gas pipelines in cold regions, and outdoor industrial machinery. Low - temperature batteries ensure that these devices can continuously monitor and transmit data, even in extreme cold.

In the automotive industry, these batteries have potential applications in electric vehicles (EVs) and hybrid vehicles. Ultra - thin batteries could be used in the interior of the vehicle to power various electronic components, such as infotainment systems and sensors. Low - temperature batteries could improve the performance of EVs in cold climates, where battery range and charging efficiency are often affected.

Challenges and Future Developments

Challenges

Despite their many advantages, rechargeable special batteries also face some challenges. One of the main challenges is the cost of production. The use of advanced materials and manufacturing techniques required to achieve low - temperature performance, ultra - thin designs, and flexibility increases the production cost of these batteries. This can make them less competitive in price - sensitive markets.

Another challenge is safety. Although significant progress has been made in battery safety technology, the use of high - energy - density materials in these special batteries can still pose safety risks, such as overheating, thermal runaway, and fire. Ensuring the safety of these batteries during charging, discharging, and storage is of utmost importance.

Future Developments

To overcome these challenges, ongoing research and development efforts are focused on reducing the production cost of rechargeable special batteries. This includes the development of new, more cost - effective materials and manufacturing processes. For example, researchers are exploring the use of alternative cathode and anode materials that can provide similar performance at a lower cost.

In terms of safety, advancements in battery management systems (BMS) are being made. BMS can monitor and control the battery's voltage, current, and temperature, preventing over - charging, over - discharging, and over - heating. Additionally, the development of self - healing battery materials and fire - resistant electrolytes could further improve the safety of these batteries.

Furthermore, future developments may include even higher energy - density rechargeable special batteries. This would allow for longer operating times and smaller battery sizes, opening up new applications in areas such as the Internet of Things (IoT), where a large number of small, low - power devices need to be powered.

Conclusion

Rechargeable special batteries, including low - temperature LiPo batteries, ultra - thin batteries, and curved batteries, represent a significant advancement in battery technology. Their unique performance characteristics, lightweight designs, and flexible form factors make them suitable for a wide range of applications across various industries. From consumer electronics to medical devices, aerospace, and industrial applications, these batteries are playing an increasingly important role in powering the devices of the future.

Although there are challenges to overcome, such as production cost and safety, ongoing research and development efforts are paving the way for more efficient, cost - effective, and safe rechargeable special batteries. As technology continues to evolve, we can expect to see even more innovative battery solutions that will further drive the development of new products and applications in the years to come.