Custom Ultra - Slim Thin 3.7V 1500mAh LiPo Battery

Custom Ultra - Slim Thin 3.7V 1500mAh LiPo Battery: A Revolution in Portable Power

Introduction

In the ever - evolving landscape of portable electronic devices, the quest for compact, lightweight, and high - capacity power sources has reached new heights. Among the various battery technologies available, Lithium - Ion Polymer (LiPo) batteries have emerged as a front - runner due to their unique properties. One particular type of LiPo battery that is gaining significant traction is the custom ultra - slim thin 3.7V 1500mAh LiPo battery, such as the 3430158 model. This article will delve into the world of these ultra - thin rechargeable 3.7V LiPo batteries, exploring their construction, applications, advantages, and the challenges faced by manufacturers in producing them.

Understanding LiPo Batteries

Basic Structure and Working Principle

A LiPo battery consists of several key components. The anode is typically made of graphite or other carbon - based materials, which serve as the site for lithium - ion storage during charging. The cathode is composed of lithium metal oxides, such as lithium cobalt oxide (LiCoO₂), lithium manganese oxide (LiMn₂O₄), or lithium iron phosphate (LiFePO₄). The electrolyte in a LiPo battery is a polymer gel or a solid - state electrolyte, which facilitates the movement of lithium ions between the anode and cathode.

During the charging process, an external power source applies a voltage to the battery. This causes lithium ions to move from the cathode through the electrolyte and separator to the anode, storing electrical energy. When the battery is discharged, the lithium ions move back from the anode to the cathode through the same path, generating an electric current that can power connected devices.

Advantages of LiPo Batteries Over Traditional Batteries

Compared to traditional battery technologies like nickel - cadmium (NiCd) or nickel - metal hydride (NiMH) batteries, LiPo batteries offer several advantages. They have a higher energy density, which means they can store more energy in a smaller and lighter package. This is crucial for portable electronic devices where space and weight are at a premium. Additionally, LiPo batteries have a lower self - discharge rate, allowing them to retain their charge for longer periods when not in use. They also have a wider operating voltage range, which provides more flexibility in device design.

Custom Ultra - Slim Thin 3.7V 1500mAh LiPo Batteries

Design and Construction Features

The ultra - slim thin design of the 3.7V 1500mAh LiPo battery is achieved through advanced manufacturing techniques. The pouch cell design, which is a common form of LiPo battery, allows for greater flexibility in shaping the battery. The polymer electrolyte used in these batteries is thin and can be easily laminated between the anode and cathode layers, contributing to the overall slimness of the battery.

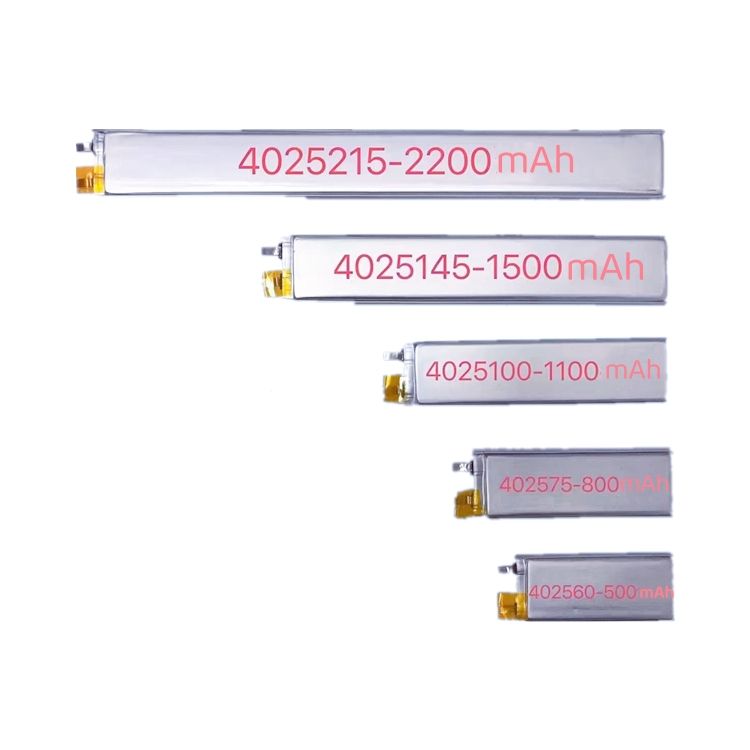

The 3430158 model, for example, has specific dimensions that are optimized for ultra - thin applications. The numbers in the model name often represent the approximate dimensions of the battery. In this case, "34" could refer to the width in millimeters, "30" to the length, and "158" might be related to the thickness or a unique identifier for the battery's internal construction.

Capacity and Voltage Considerations

The 3.7V nominal voltage of these LiPo batteries is a standard in the industry, making them compatible with a wide range of electronic devices. The 1500mAh capacity provides a balance between power delivery and battery size. For devices that require a moderate amount of power over an extended period, such as smartwatches, fitness trackers, or some small Bluetooth speakers, this capacity is often sufficient.

However, it is important to note that the actual usable capacity of the battery may vary depending on factors such as the discharge rate, temperature, and the device's power management system. Manufacturers often specify the battery's capacity at a certain discharge rate, and using the battery at a higher discharge rate may result in a lower effective capacity.

Applications of Custom Ultra - Slim Thin 3.7V 1500mAh LiPo Batteries

Wearable Technology

Wearable devices, such as smartwatches, fitness bands, and augmented reality (AR) glasses, are prime candidates for ultra - slim thin LiPo batteries. These devices need to be lightweight, comfortable to wear, and have a long - lasting battery life. The 3.7V 1500mAh LiPo batteries can fit seamlessly into the compact designs of wearable technology, providing the necessary power for features like heart rate monitoring, step counting, and wireless communication.

Medical Devices

In the medical field, portable and wearable medical devices are becoming increasingly popular. Devices such as continuous glucose monitors (CGMs), portable electrocardiogram (ECG) machines, and hearing aids require reliable and compact power sources. The ultra - slim thin LiPo batteries can meet the stringent requirements of medical applications, including long battery life, safety, and compatibility with the device's form factor.

Consumer Electronics

Small consumer electronics, such as wireless earbuds, portable gaming devices, and miniature cameras, also benefit from the use of ultra - slim thin LiPo batteries. These devices aim to be as portable and unobtrusive as possible, and the slim batteries allow for sleeker designs without sacrificing battery performance.

Manufacturing Process of Ultra - Thin Rechargeable 3.7V LiPo Batteries

Material Selection

The selection of materials is a critical step in the manufacturing process of ultra - thin LiPo batteries. High - quality anode and cathode materials are essential for achieving good battery performance. For the anode, graphite with a high purity and specific particle size distribution is often used. On the cathode side, lithium metal oxides with a well - controlled crystal structure are selected to ensure efficient lithium - ion storage and release.

The polymer electrolyte is another key material. It needs to have good ionic conductivity at low temperatures, high mechanical strength to prevent short - circuits, and chemical stability to withstand the electrochemical reactions within the battery. Manufacturers often work with specialized suppliers to source the best materials for their ultra - thin LiPo batteries.

Layer Lamination and Assembly

The layer lamination process involves combining the anode, cathode, and electrolyte layers into a single pouch cell. This is done using precision equipment that ensures accurate alignment and thickness control of each layer. The pouch material, usually a multi - layer laminate, provides protection for the battery's internal components and acts as a barrier against moisture and oxygen.

After lamination, the battery cells are assembled into packs, which may include multiple cells connected in series or parallel to achieve the desired voltage and capacity. Battery management systems (BMS) are also integrated into the packs to monitor and control the battery's performance, including voltage, current, and temperature.

Quality Control and Testing

Quality control is of utmost importance in the manufacturing of ultra - thin LiPo batteries. Stringent testing procedures are carried out at various stages of the production process. These tests include electrical performance tests, such as capacity measurement, internal resistance testing, and cycle life testing. Safety tests, such as overcharge, over - discharge, and short - circuit tests, are also performed to ensure that the batteries meet international safety standards.

Advantages of Custom Ultra - Slim Thin 3.7V 1500mAh LiPo Batteries

Compact and Lightweight Design

The most obvious advantage of ultra - slim thin LiPo batteries is their compact and lightweight design. This allows device manufacturers to create thinner and more portable products without compromising on battery performance. In today's market, where consumers demand sleek and stylish devices, the slim batteries provide a significant competitive edge.

High Energy Density per Unit Volume

Despite their thin profile, these LiPo batteries offer a relatively high energy density per unit volume. This means that they can store a significant amount of energy in a small space, providing longer battery life for devices. For example, a smartwatch equipped with an ultra - slim thin LiPo battery can operate for several days on a single charge, enhancing the user experience.

Flexibility in Design Integration

The pouch cell design of ultra - thin LiPo batteries provides manufacturers with greater flexibility in integrating the batteries into their devices. The batteries can be bent or shaped to fit the unique contours of a device, allowing for more innovative and ergonomic designs. This is particularly beneficial for wearable technology, where the battery needs to conform to the shape of the human body.

Challenges Faced by Manufacturers

Production Yield and Consistency

Producing ultra - thin LiPo batteries with high yield and consistency is a significant challenge. The thin layers of the battery components are delicate and can be easily damaged during the manufacturing process. Any defects in the layer lamination or assembly can lead to reduced battery performance or even safety issues. Manufacturers need to invest in advanced production equipment and quality control systems to ensure that each battery meets the required specifications.

Safety Concerns

LiPo batteries, in general, pose certain safety risks if they are misused or damaged. Ultra - thin LiPo batteries are no exception. The thin pouch material can be more susceptible to punctures or tears, which could result in a short - circuit and thermal runaway. Manufacturers must implement robust safety measures, such as overcharge protection circuits, thermal fuses, and proper packaging, to minimize these risks.

Cost Considerations

The production of ultra - thin LiPo batteries often involves more complex manufacturing processes and the use of specialized materials. This can lead to higher production costs compared to traditional battery technologies. Manufacturers need to balance the cost of production with the market demand for these batteries and find ways to optimize their processes to reduce costs while maintaining quality.

Future Trends and Developments

Increased Energy Density

Researchers and manufacturers are constantly working on improving the energy density of LiPo batteries. New materials and battery architectures are being explored to store more lithium ions and increase the battery's capacity without increasing its size. This could lead to even longer - lasting ultra - slim thin LiPo batteries in the future, opening up new possibilities for device design and functionality.

Faster Charging

Another area of development is faster charging technology. Ultra - slim thin LiPo batteries that can be charged quickly would be highly desirable for consumers who want to minimize downtime. Manufacturers are investigating new charging algorithms and battery materials that can support higher charging rates without compromising battery safety or longevity.

Sustainability

As environmental concerns become more prominent, there is a growing demand for sustainable battery solutions. Manufacturers are looking into ways to reduce the environmental impact of LiPo battery production, such as using recycled materials, improving the battery's recyclability, and developing more energy - efficient manufacturing processes.

Conclusion

Custom ultra - slim thin 3.7V 1500mAh LiPo batteries, like the 3430158 model, represent a significant advancement in battery technology. Their compact design, high energy density, and flexibility in integration make them ideal for a wide range of applications, from wearable technology to medical devices and consumer electronics. Despite the challenges faced by manufacturers in terms of production yield, safety, and cost, ongoing research and development efforts are likely to further improve the performance and reduce the drawbacks of these batteries. As the demand for portable and compact electronic devices continues to grow, ultra - slim thin LiPo batteries will play an increasingly important role in powering the technology of the future.