Customized Ultra-Thin 3.0V CP401830 400mAh Pouch Lithium Manganese (Li-MnO₂) Battery for E-Tags and Access Cards

Customized Ultra-Thin 3.0V CP401830 400mAh Pouch Lithium Manganese (Li-MnO₂) Battery for E-Tags and Access Cards

1. Introduction

In the era of intelligent connectivity and miniaturization, the demand for compact, high-performance power sources has surged exponentially. From electronic toll collection (ETC) tags that streamline highway travel to contactless access cards that secure office buildings and residential complexes, the functionality of these small-scale electronic devices hinges entirely on the reliability and efficiency of their internal batteries. Among the diverse range of battery technologies available today, the customized ultra-thin battery 3.0V CP401830 400mAh pouch lithium manganese (Li-MnO₂) battery has emerged as a standout solution, perfectly tailored to meet the unique requirements of E-tags and access cards.

This article delves into every aspect of the CP401830 400mAh Li-MnO₂ soft pack battery, exploring its technical specifications, structural design, performance advantages, manufacturing processes, application-specific optimizations for E-tags and access cards, quality control measures, and future development prospects. By dissecting the features that make this battery a preferred choice for low-power, miniaturized electronics, we aim to provide a comprehensive understanding of how it addresses the evolving needs of the smart device industry.

2. Overview of Lithium Manganese (Li-MnO₂) Battery Technology

Before delving into the specifics of the CP401830 400mAh pouch battery, it is essential to establish a foundational understanding of lithium manganese dioxide (Li-MnO₂) battery technology, the core chemistry that underpins its performance. Li-MnO₂ batteries belong to the primary lithium battery family, meaning they are non-rechargeable (primary cells) and designed for single-use applications where long-term, stable discharge and minimal maintenance are critical.

2.1 Core Chemistry and Working Principle

The Li-MnO₂ battery operates on a simple yet efficient electrochemical reaction. The anode (negative electrode) is typically composed of metallic lithium, which serves as the source of lithium ions (Li⁺). The cathode (positive electrode) is made of manganese dioxide (MnO₂), a stable and abundant material that acts as the host for lithium ions during discharge. The electrolyte, usually a lithium salt (such as LiClO₄ or LiBF₄) dissolved in an organic solvent (e.g., propylene carbonate or dimethyl carbonate), facilitates the movement of lithium ions between the anode and cathode.

During discharge, lithium metal at the anode undergoes oxidation, releasing lithium ions and electrons. The electrons flow through the external circuit (powering the connected device, such as an E-tag or access card), while the lithium ions migrate through the electrolyte to the cathode. At the cathode, the lithium ions, electrons, and MnO₂ react to form lithium manganese oxide (LiMnO₂), a stable compound that stores the energy released during the reaction. This reaction is characterized by a flat discharge voltage curve, ensuring consistent power output throughout the battery’s lifespan—a key advantage for devices that require steady voltage to function properly.

2.2 Key Advantages of Li-MnO₂ Batteries

Li-MnO₂ batteries offer several inherent advantages that make them ideal for small electronic devices like E-tags and access cards:

Stable Discharge Voltage: With a nominal voltage of 3.0V, Li-MnO₂ batteries provide a consistent voltage output over most of their discharge cycle. This stability is crucial for E-tags, which rely on consistent power to transmit radio frequency (RF) signals, and access cards, which need reliable energy to power their contactless chips.

High Energy Density: Compared to traditional primary batteries like alkaline or zinc-carbon batteries, Li-MnO₂ batteries boast higher energy density (typically 280–350 Wh/kg). This means they can store more energy in a smaller, lighter package—essential for ultra-thin devices where space is at a premium.

Long Shelf Life: Li-MnO₂ batteries have an extremely low self-discharge rate (usually less than 1% per year at room temperature). This allows them to retain their charge for up to 10 years when stored properly, making them ideal for E-tags and access cards, which often have a service life of 5–8 years and require minimal maintenance.

Wide Operating Temperature Range: Most Li-MnO₂ batteries can operate reliably within a temperature range of -20°C to 60°C, and customized versions (like the CP401830) can be optimized for even broader ranges. This versatility ensures functionality in harsh environments, such as hot summer highways (for E-tags) or cold outdoor parking lots (for access cards).

Safety and Environmental Friendliness: Manganese dioxide is a non-toxic, abundant material, and Li-MnO₂ batteries do not contain heavy metals like mercury or cadmium. Additionally, their stable chemistry minimizes the risk of leakage or thermal runaway, making them safe for use in consumer and commercial devices.

3. Technical Specifications and Structural Design of the ultra thin battery CP401830 400mAh Pouch Battery

The CP401830 400mAh pouch lithium manganese battery is a customized ultra-thin solution engineered specifically for the constraints of E-tags and access cards. Its model number—CP401830—provides key insights into its physical dimensions: “40” refers to the length (40mm), “18” to the width (18mm), and “30” to the thickness (3.0mm). This compact form factor, combined with a 400mAh capacity and 3.0V nominal voltage, makes it a perfect fit for devices that require both small size and long-lasting power.

3.1 Detailed Technical Specifications

To fully appreciate the performance of the ultra thin CP401830 battery, it is essential to examine its detailed technical parameters, which are tailored to the needs of E-tags and access cards:

3.2 Structural Design: The Pouch (Soft Pack) Advantage

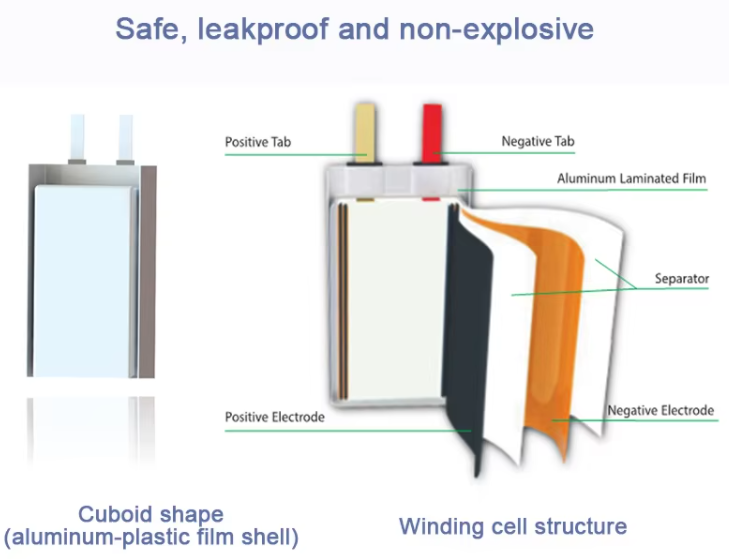

The CP401830 battery adopts a pouch (soft pack) design, which is a critical differentiator from traditional cylindrical or prismatic hard-case batteries. This design offers several advantages for E-tags and access cards:

3.2.1 Ultra-Thin Profile

Unlike hard-case batteries, which require a rigid metal or plastic shell to contain the electrodes and electrolyte, pouch batteries use a flexible, multi-layered film (typically composed of polyethylene terephthalate, aluminum foil, and polypropylene) as the outer casing. This film is thin (as little as 0.1mm per layer) and lightweight, allowing the battery to achieve a thickness of just 3.0mm—far thinner than cylindrical batteries of similar capacity (which often have a diameter of 10mm or more). This ultra-thin profile is essential for E-tags and access cards, which must be slim enough to attach to windshields (E-tags) or fit in wallets (access cards).

3.2.2 Flexible Form Factor

The flexible film casing of the pouch battery allows for minor adjustments in shape during manufacturing and assembly. This flexibility is particularly useful for E-tags, which may have curved or irregular designs to fit windshields, and access cards, which may need to conform to standard card sizes while accommodating other components (like RFID chips). Unlike hard-case batteries, which have fixed shapes, pouch batteries can be slightly compressed or bent without compromising performance—reducing the risk of damage during device assembly or daily use.

3.2.3 High Energy Density

The absence of a rigid casing means that more space in the battery can be dedicated to active materials (lithium anode, MnO₂ cathode, and electrolyte). This results in a higher energy density compared to hard-case batteries of the same size. For the CP401830, this translates to a 400mAh capacity in a 40mm×18mm×3.0mm package—enough to power an E-tag for years without needing replacement.

3.2.4 Enhanced Safety

The pouch film casing is designed to be breathable, meaning it can release gas (if any is generated during abnormal operation) slowly, reducing the risk of explosion or leakage. Additionally, the flexible casing is less prone to cracking or denting than hard cases, which can rupture and cause electrolyte leakage. For E-tags, which are mounted on car windshields (exposed to temperature fluctuations and vibrations), and access cards, which are carried in wallets (subject to pressure and bending), this enhanced safety is a critical feature.

4. Application-Specific Optimization for E-Tags

Electronic toll collection (ETC) tags, also known as E-tags, are one of the primary applications for the CP401830 400mAh pouch battery. E-tags are small, wireless devices mounted on a vehicle’s windshield that communicate with toll booth readers to automatically deduct toll fees, eliminating the need for manual payment. The performance requirements of E-tags are unique: they must operate continuously for years in harsh outdoor environments, consume minimal power (to extend battery life), and transmit reliable RF signals when passing through toll plazas. The CP401830 battery is optimized to meet all these requirements, making it an ideal power source for E-tags.

4.1 Power Consumption Matching

E-tags have two main power-consuming components: the RFID chip (which stores vehicle and account information) and the RF transmitter (which sends data to the toll reader). The power consumption of these components is extremely low:

Standby Mode: When the vehicle is not near a toll plaza, the E-tag remains in standby mode, with only the RFID chip’s memory powered. This mode consumes just 0.05–0.1mAh per day.

Active Mode: When the vehicle approaches a toll plaza (within 5–10 meters of the reader), the E-tag switches to active mode, activating the RF transmitter to send data. This mode consumes a short burst of power (typically 20–50mA for 1–2 seconds per transaction).

The CP401830 battery’s 400mAh capacity and low self-discharge rate are perfectly matched to this consumption pattern. Even with daily toll transactions (2–3 active mode cycles per day), the battery can provide power for 5–8 years—far exceeding the typical service life of an E-tag (which is 5 years on average). Additionally, the battery’s maximum pulse current of 400mA ensures that the RF transmitter has enough power to send a strong, reliable signal, even in adverse conditions (like rain or fog, which can weaken RF signals).

4.2 Temperature Resistance for Outdoor Use

E-tags are exposed to extreme temperature fluctuations, from freezing winters (-20°C or lower in cold regions) to scorching summers (60°C or higher inside a parked car). Standard batteries often struggle in these conditions: low temperatures can reduce discharge capacity and slow down ion movement, while high temperatures can accelerate self-discharge and degrade active materials.

The CP401830 battery is customized with a temperature-resistant electrolyte and modified electrode materials to operate reliably within a range of -25°C to 70°C. At -25°C, the battery retains over 70% of its nominal capacity, ensuring that the E-tag can still transmit signals in freezing weather. At 70°C, the battery’s self-discharge rate remains below 1% per year, preventing premature capacity loss in hot conditions. This temperature resistance is achieved through several modifications:

Electrolyte Optimization: The electrolyte uses a mixture of high-boiling-point organic solvents (e.g., ethylene carbonate and dimethyl carbonate) that remain liquid at low temperatures and stable at high temperatures.

Cathode Coating: The MnO₂ cathode is coated with a thin layer of carbon to improve electron conductivity at low temperatures, reducing voltage drop during discharge.

Anode Protection: The lithium anode is treated with a protective film that prevents corrosion at high temperatures, extending the battery’s lifespan.

4.3 Vibration and Shock Resistance

Vehicles experience constant vibration while driving, and E-tags (mounted on windshields) are exposed to these vibrations daily. Additionally, sudden shocks (like potholes or collisions) can damage internal components of the E-tag, including the battery. The CP401830 battery’s pouch design and internal structure are optimized to withstand these mechanical stresses.

The flexible pouch casing absorbs vibrations and shocks, reducing the impact on the internal electrodes and electrolyte. Inside the battery, the electrodes are laminated (instead of rolled, as in cylindrical batteries) to create a flat, stable structure that resists shifting during vibration. The electrolyte is also gelled (a modified version of liquid electrolyte) to prevent leakage if the pouch is slightly damaged. These design features ensure that the battery remains functional even after years of exposure to vehicle vibrations and occasional shocks.

5. Application-Specific Optimization for Access Cards

Access cards (also known as proximity cards or contactless access cards) are another key application for the CP401830 400mAh pouch battery. These cards are used to grant access to buildings, offices, parking lots, and other secure areas by communicating wirelessly with a card reader (typically via RFID or NFC technology). Access cards have distinct requirements: they must be slim and lightweight (to fit in wallets), have a long service life (to avoid frequent replacements), and operate reliably in indoor environments (with moderate temperature fluctuations and minimal vibration). The CP401830 battery is tailored to meet these needs, making it a preferred choice for high-performance access cards.

5.1 Slim Form Factor for Wallet Compatibility

Standard access cards (CR80 size) have dimensions of 85.6mm × 54mm × 0.76mm—similar to a credit card. However, contactless access cards with batteries (known as “active” access cards) require additional space for the battery and RFID chip. The CP401830 battery’s ultra-thin profile (3.0mm thickness) and compact dimensions (40mm × 18mm) allow it to fit within the thickness constraints of active access cards (which typically range from 2.5mm to 4mm). This slim form factor ensures that the access card remains lightweight and easy to carry in a wallet or pocket—unlike bulkier access cards powered by cylindrical batteries.

Additionally, the battery’s flexible pouch design allows it to be placed in non-central areas of the card (e.g., along the edge), leaving space for the RFID chip and antenna. This flexibility in placement is crucial for access card designers, who need to optimize the card’s layout for maximum RF signal strength (the antenna must be positioned to communicate effectively with the reader).

5.2 Low Power Consumption for Long Lifespan

Active access cards consume power in two modes:

Standby Mode: The card remains in standby mode when not near a reader, with only the RFID chip’s memory powered. This mode consumes approximately 0.03–0.08mAh per day—even lower than E-tags.

Active Mode: When the card is held near a reader (within 1–2 meters), it activates the RFID chip and antenna to transmit access credentials. This mode consumes a short pulse of power (10–30mA for 0.5–1 second per use).