Lipo Battery: The Ultimate Power Solution for Sensor Equipment – High Energy Density, Long Cycle Life & Uncompromised Safety

Lipo Battery: The Ultimate Power Solution for Sensor Equipment – High Energy Density, Long Cycle Life & Uncompromised Safety

In the era of IoT and smart technology, sensor equipment has become the backbone of industries ranging from industrial automation and environmental monitoring to healthcare and smart cities. These compact, mission-critical devices rely heavily on a power source that can keep up with their demands: high energy density to support long-term operation, lightweight design to fit tight form factors, long cycle life to reduce maintenance costs, and uncompromised safety to protect both the device and its surroundings. For engineers and procurement professionals seeking the perfect battery solution, the Lipo battery (lithium polymer battery) stands out as the gold standard—and Serui Battery’s 3.7V 400mAh 602035 Pouch Li-ion Rechargeable Battery is redefining what a lithium polymer battery can deliver for sensor equipment.

Why Lipo Battery Dominates the Sensor Equipment Market

Sensor equipment operates in diverse and often challenging environments: from industrial warehouses with fluctuating temperatures to remote outdoor locations where frequent battery replacement is impractical. This is where the unique advantages of a lithium polymer battery shine. Unlike traditional nickel-cadmium (NiCd) or nickel-metal hydride (NiMH) batteries, Lipo batteries offer a combination of performance metrics that align perfectly with the needs of sensor technology.

First and foremost, high energy density is a non-negotiable requirement for sensors. These devices are typically compact, with limited space for batteries, yet they need to run continuously for weeks, months, or even years on a single charge. Serui’s 3.7V 400mAh Lipo battery boasts an impressive energy density of up to 200 Wh/kg, meaning it can store more energy per unit weight than most conventional batteries. For a small sensor device, this translates to extended runtime without sacrificing size or adding unnecessary bulk. Imagine a environmental monitoring sensor deployed in a remote forest: with a high-energy-density lithium polymer battery, it can collect and transmit data for months without human intervention, reducing operational costs and ensuring uninterrupted data collection.

Second, lightweight design is critical for sensor equipment, especially those that are portable, wearable, or mounted on moving parts. Lipo batteries are constructed using flexible polymer electrolytes instead of rigid metal casings, making them significantly lighter than lithium-ion cylindrical batteries of the same capacity. Serui’s 602035 pouch Lipo battery weighs just 12 grams—nearly 30% lighter than a comparable cylindrical lithium-ion battery. This lightweight advantage is a game-changer for applications like wearable health sensors, where comfort and unobtrusiveness are key, or for drone-mounted sensors, where every gram affects flight time and maneuverability.

Third, long cycle life ensures that sensor equipment remains cost-effective over its lifespan. Frequent battery replacement not only increases maintenance costs but also risks downtime in critical applications (e.g., industrial process monitoring or medical sensors). Serui’s lithium polymer battery is engineered to withstand over 500 charge-discharge cycles while retaining more than 80% of its original capacity. This means that for a sensor operating 24/7, the battery can last for over a year before needing replacement—far outperforming NiCd batteries (which typically offer 300-400 cycles) and even some lower-quality Lipo batteries on the market.

Last but certainly not least, safety is paramount when it comes to powering sensor equipment. Many sensors are used in sensitive environments, such as hospitals, data centers, or explosive industrial zones, where a battery failure could have catastrophic consequences. Serui’s Lipo battery incorporates multiple safety features to mitigate risks: a built-in protection circuit module (PCM) that prevents overcharging, over-discharging, and short circuits; a flame-retardant polymer casing that resists thermal runaway; and strict quality control processes that ensure each battery meets international safety standards (UN38.3, IEC 62133, RoHS). Unlike some lithium-ion batteries that pose fire or explosion risks if mishandled, Serui’s lithium polymer battery is designed to be reliable and safe, even in extreme operating conditions.

Serui’s 3.7V 400mAh 602035 Lipo Battery: Tailored for Sensor Equipment

While the benefits of Lipo batteries are clear, not all lithium polymer batteries are created equal. Serui Battery, a leading manufacturer with years of experience in battery technology, has developed the 602035 pouch Lipo battery specifically to address the unique needs of sensor equipment. Let’s take a closer look at what sets this battery apart.

1. Optimized Form Factor for Tight Spaces

Sensor equipment is often designed with miniaturization in mind, which means battery compartments are frequently small and irregularly shaped. The 602035 Lipo battery features a slim, flexible pouch design (6.0mm thickness × 20mm width × 35mm length) that can fit into tight spaces that cylindrical batteries cannot. Its flexible construction also allows for minor adjustments to fit custom battery compartments, making it an ideal choice for engineers working on prototype or custom sensor designs. Whether you’re building a tiny wearable sensor or a compact industrial monitoring device, this lithium polymer battery’s form factor ensures seamless integration without compromising performance.

2. Consistent Performance Across Environments

Sensors often operate in extreme temperatures, from freezing cold (-20℃) to scorching heat (60℃). Serui’s Lipo battery is tested to perform reliably across a wide temperature range, with minimal capacity loss even in harsh conditions. At -10℃, it retains 85% of its capacity, and at 45℃, it maintains 90%—far exceeding the performance of many standard Lipo batteries. This consistency is crucial for sensors deployed in outdoor or industrial environments, where temperature fluctuations are common. For example, a sensor monitoring pipeline pressure in a desert environment can rely on Serui’s lithium polymer battery to deliver stable power even during peak daytime heat.

3. Low Self-Discharge Rate for Long-Term Storage

Many sensors are not used continuously; some are deployed for seasonal monitoring or kept in storage as backups. A high self-discharge rate can render a battery useless if it’s not charged regularly. Serui’s Lipo battery has a self-discharge rate of less than 3% per month, meaning it can retain 90% of its charge for up to a year in storage. This is a significant advantage for sensor manufacturers and end-users alike: it reduces the need for pre-deployment charging and ensures that backup sensors are ready to use when needed.

4. Eco-Friendly and Compliant with Global Standards

In today’s environmentally conscious market, compliance with eco-friendly standards is more important than ever. Serui’s lithium polymer battery is RoHS-compliant, meaning it contains no harmful substances such as lead, mercury, or cadmium. It also meets UN38.3 transportation standards, ensuring safe shipping worldwide. For businesses operating in regions with strict environmental regulations (e.g., the EU, North America), this compliance eliminates the risk of non-compliance penalties and enhances brand reputation as a responsible supplier.

Real-World Applications: How Serui’s Lipo Battery Powers Sensor Equipment

To understand the impact of Serui’s lithium polymer battery, let’s explore some real-world applications where it has proven to be a reliable power solution.

Industrial Automation Sensors

In manufacturing facilities, sensors are used to monitor machine performance, detect defects, and ensure worker safety. These sensors operate 24/7 and are often mounted in hard-to-reach locations, making battery replacement time-consuming and costly. A leading industrial automation company switched to Serui’s 3.7V 400mAh Lipo battery for their vibration sensors and saw a 40% reduction in maintenance costs due to the battery’s long cycle life (over 500 cycles) and extended runtime. The battery’s high energy density also allowed the company to reduce the size of their sensors, making them easier to install on compact machinery.

Environmental Monitoring Sensors

Environmental agencies and research institutions rely on sensors to monitor air quality, water levels, and wildlife activity in remote areas. A global environmental research organization uses Serui’s Lipo battery in their weather sensors deployed in the Arctic. The battery’s ability to perform at low temperatures (-20℃) and its lightweight design (12 grams) were key factors in the decision. The sensors have been operating continuously for 18 months without battery replacement, providing valuable data on climate change.

Wearable Health Sensors

Wearable health devices, such as fitness trackers and medical monitors, require batteries that are lightweight, compact, and safe for prolonged skin contact. A leading healthcare technology company chose Serui’s lithium polymer battery for their portable ECG monitors. The battery’s slim form factor (6.0mm thickness) fits comfortably in the device’s wristband, while its high energy density supports 72 hours of continuous monitoring on a single charge. The battery’s safety features, including overcharge protection, also give users peace of mind when wearing the device for extended periods.

Smart Home Sensors

Smart home sensors (e.g., motion detectors, door/window sensors) need to be discreet and reliable, with long battery life to avoid frequent replacements. A major smart home brand integrated Serui’s 602035 Lipo battery into their motion sensors and saw a 30% increase in customer satisfaction due to the battery’s 12-month runtime. The battery’s low self-discharge rate also ensures that sensors remain operational even if the home is unoccupied for extended periods (e.g., during vacations).

Why Choose Serui Battery for Your Lipo Battery Needs?

With so many lithium polymer battery manufacturers on the market, why should you choose Serui Battery? Here are four compelling reasons:

1. Expertise in Custom Battery Solutions

Serui Battery has over a decade of experience designing and manufacturing Lipo batteries for a wide range of applications, including sensor equipment. Our engineering team works closely with clients to understand their specific requirements (e.g., size, capacity, operating temperature) and develop custom solutions that meet or exceed their expectations. Whether you need a standard battery like the 3.7V 400mAh 602035 or a fully customized lithium polymer battery, we have the expertise to deliver.

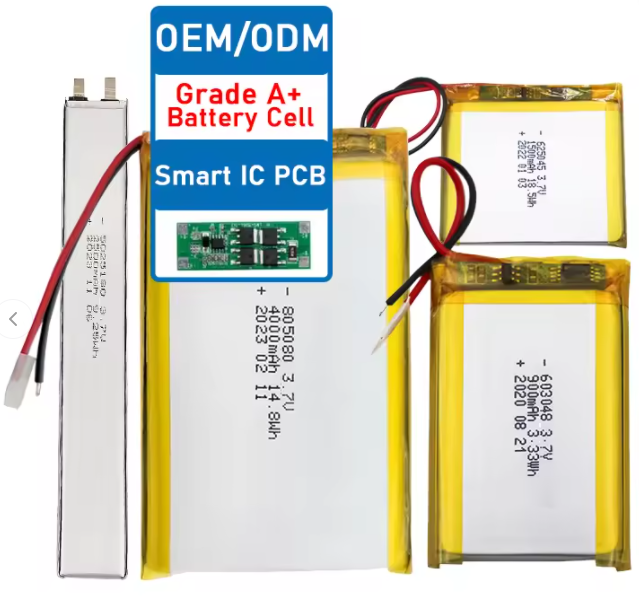

2. Strict Quality Control Processes

Quality is at the heart of everything we do. Each Lipo battery undergoes rigorous testing throughout the manufacturing process, including capacity testing, cycle life testing, safety testing, and environmental testing. We use only high-quality materials (e.g., grade A lithium-ion cells, flame-retardant polymers) to ensure that every battery is reliable and durable. Our quality control processes are certified to ISO 9001 standards, giving you confidence in the performance of our products.

3. Competitive Pricing and Fast Lead Times

We understand that cost and speed are critical factors for businesses. By optimizing our manufacturing processes and leveraging economies of scale, we offer competitive pricing on our lithium polymer batteries without compromising quality. We also maintain a large inventory of standard products, such as the 602035 Lipo battery, to ensure fast lead times (typically 3-5 working days for standard orders). For custom orders, we work efficiently to deliver samples within 7-10 working days and mass production within 3-4 weeks.

4. Exceptional Customer Support

At Serui Battery, we believe in building long-term relationships with our clients. Our customer support team is available 24/7 to answer your questions, provide technical assistance, and address any issues you may have. Whether you need help selecting the right Lipo battery for your sensor equipment or require after-sales support, we’re here to help. We also provide detailed technical documentation, including data sheets and safety certificates, to make integration as smooth as possible.

Conclusion: Invest in the Best Lipo Battery for Your Sensor Equipment

Sensor equipment is only as reliable as its power source. For applications that demand high energy density, long cycle life, lightweight design, and uncompromised safety, the Lipo battery (lithium polymer battery) is the clear choice. Serui Battery’s 3.7V 400mAh 602035 Pouch Li-ion Rechargeable Battery is engineered to meet the unique needs of sensor equipment, with a focus on performance, durability, and safety.

Whether you’re designing a new sensor product, upgrading an existing device, or looking for a cost-effective battery solution for mass production, Serui Battery has you covered. Our commitment to quality, expertise in custom solutions, and exceptional customer support make us the trusted partner for businesses worldwide.

Visit www.serui-battery.com today to learn more about our Lipo battery products, download technical data sheets, or request a quote. Let us help you power your sensor equipment with the best lithium polymer battery on the market—reliable, efficient, and built to last.