3.6V LiSOCl₂ Batteries: ER26500 SPC1550, SPC1520 with ER14250, ER14505, ER17505, ER18505, and ER34615

3.6V LiSOCl₂ Batteries: ER26500 SPC1550, SPC1520 with ER14250, ER14505, ER17505, ER18505, and ER34615

Abstract

Lithium thionyl chloride (LiSOCl₂) batteries are the backbone of modern IoT, industrial automation, and remote sensing applications due to their high energy density, stable voltage output, and exceptional longevity. Among these, the 3.6V ER26500 and its variants (SPC1550, SPC1520) have emerged as industry favorites, while other models like ER14250, ER14505, ER17505, ER18505, and ER34615 cater to niche requirements. This article provides an in-depth analysis of these batteries, covering technical specifications, performance comparisons, customization options, and real-world applications to guide engineers and procurement specialists in selecting the optimal power solution.

1. Introduction to LiSOCl₂ Battery Technology

LiSOCl₂ batteries belong to the primary lithium family, distinguished by their lithium anode and thionyl chloride (SOCl₂) electrolyte. This chemistry offers:

Ultra-high energy density: Up to 720 Wh/kg, surpassing alkaline and Li-MnO₂ batteries.

Stable 3.6V nominal voltage: Ideal for low-power devices requiring consistent output.

Low self-discharge rate: <1% per year at 20°C, enabling 10+ years of shelf life.

Wide temperature tolerance: Operational range of -40°C to +85°C, suitable for extreme environments.

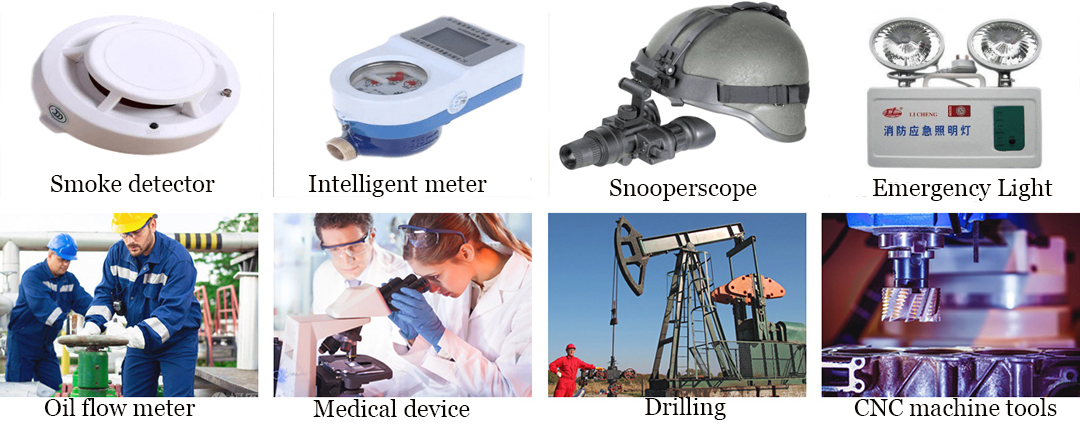

These attributes make LiSOCl₂ batteries indispensable for applications where longevity, reliability, and minimal maintenance are critical, such as IoT meters, medical devices, and aerospace systems.

2. Overview of Key Models: ER26500, SPC1550, SPC1520, and Comparators

2.1 ER26500: The C-Size Workhorse

Dimensions: 26.2mm (diameter) × 50.0mm (length).

Capacity: 8,500mAh (typical).

Key Features:

Standard C-size form factor, compatible with most off-the-shelf holders.

Balanced performance for moderate-drain applications (e.g., smart meters, GPS trackers).

Cost-effective for high-volume deployments.

2.2 SPC1550 and SPC1520: Customized Variants

SPC1550:

Dimensions: 26mm × 15.5mm (ultra-slim profile).

Capacity: ~6,000mAh (optimized for space constraints).

Target Applications: Wearable sensors, compact IoT nodes.

SPC1520:

Dimensions: 26mm × 15.2mm (even thinner).

Capacity: ~5,500mAh.

Target Applications: Medical implants, RFID tags.

2.3 Comparative Models: ER14250, ER14505, ER17505, ER18505, ER34615

ER14250 | 14.5 | 25.0 | 1,200 | Memory backup, small sensors |

ER14505 | 14.5 | 50.5 | 2,400 | Industrial alarms, security systems |

ER17505 | 17.0 | 50.5 | 3,600 | Medical devices, wireless communication |

ER18505 | 18.5 | 50.5 | 4,500 | AMR meters, environmental monitors |

ER34615 | 34.0 | 61.5 | 19,000 | High-drain applications (e.g., oil & gas telemetry) |

3. Technical Specifications and Performance Analysis

3.1 Core Parameters

Voltage Stability: LiSOCl₂ batteries exhibit a flat discharge curve, maintaining >3.3V until near depletion, which simplifies power management in low-voltage circuits.

Internal Resistance: Lower resistance (e.g., <200mΩ for ER26500) enables higher pulse currents (up to 200mA for short durations), critical for wireless transmission.

Self-Discharge: All models retain >90% capacity after 10 years at 20°C, outperforming alkaline (50% loss in 3–5 years) and Li-FeS₂ (80% loss in 7 years).

3.2 Temperature Performance

Cold Environments (-40°C to 0°C):

Capacity retention: 70–85% of nominal value.

Use Case: Arctic weather stations, frozen storage monitors.

High Temperatures (60°C to 85°C):

Capacity retention: 90–95% but accelerated self-discharge (~2% per year).

Use Case: Desert solar tracking systems, automotive sensors.

3.3 Energy Density Comparison

ER26500: 650 Wh/kg (highest among mid-size models).

ER34615: 720 Wh/kg (industry leader for high-capacity needs).

ER14250: 420 Wh/kg (compromises energy density for compact size).

4. Customization Options for Diverse Applications

4.1 Form Factor Adaptations

Coiled Designs: For cylindrical spaces (e.g., pipeline pressure sensors).

Prismatic Cells: Flat packaging for smart cards or thin wearables.

Custom Labels/Packaging: Branding, QR codes, or tamper-evident seals for supply chain security.

4.2 Electrical Enhancements

Hybrid Layers: Combining LiSOCl₂ with a Li-MnO₂ cathode improves high-rate discharge performance for devices requiring frequent bursts (e.g., LoRaWAN transmitters).

Protected Circuits: Over-discharge, over-current, and short-circuit protection for safety-critical applications (e.g., gas leak detectors).

4.3 Environmental Adaptations

Hermetic Sealing: For underwater or corrosive environments (e.g., marine buoys).

High-Temperature Electrolytes: Special formulations for operation beyond 85°C (e.g., geothermal sensors).

5. Real-World Applications and Case Studies

5.1 Smart Energy Meters (ER26500, ER18505)

Challenge: Powering automatic meter reading (AMR) devices for 10+ years without battery replacement.

Solution: ER26500’s 8,500mAh capacity supports daily wireless transmissions for over a decade, while ER18505’s 4,500mAh suffices for less frequent updates (e.g., weekly readings).

Outcome: Reduced maintenance costs and improved data accuracy for utilities.

5.2 Agricultural IoT (SPC1520, ER14250)

Challenge: Deploying soil moisture sensors in remote fields with no power infrastructure.

Solution: SPC1520’s slim profile fits into compact sensor housings, while ER14250’s 1,200mAh capacity powers low-power LoRa modules for 5+ years.

Outcome: Enhanced crop yields through precision irrigation, with minimal field visits.

5.3 Industrial Automation (ER34615)

Challenge: Powering SCADA system sensors in oil refineries exposed to high temperatures and vibrations.

Solution: ER34615’s 19,000mAh capacity and rugged design support continuous operation for 15+ years, even in harsh conditions.

Outcome: Prevented downtime worth millions of dollars in lost production.

6. Challenges and Mitigation Strategies

6.1 High Initial Cost

Issue: LiSOCl₂ batteries cost 3–5× more than alkaline cells upfront.

Mitigation: Emphasize total cost of ownership (TCO) calculations. For example, replacing an alkaline battery every 2 years in a smart meter costs

8 for a single ER26500.

6.2 Transportation Restrictions

Issue: Lithium batteries are classified as Class 9 hazardous materials under IATA/DOT regulations.

Mitigation: Partner with certified logistics providers and use UN-approved packaging (e.g., PI 965 Section II for small quantities).

6.3 Recycling and Sustainability

Issue: While non-toxic, lithium batteries require proper recycling to recover cobalt and lithium.

Mitigation: Collaborate with e-waste recyclers like Call2Recycle or offer take-back programs to end-users.

7. Future Trends in LiSOCl₂ Battery Technology

7.1 Integration with Energy Harvesting

Hybrid systems combining LiSOCl₂ batteries with solar or RF energy harvesting could extend IoT device lifespans to 20+ years, enabling "fit-and-forget" deployments in smart cities.

7.2 Advances in Battery Management ICs

Smart power chips will optimize discharge profiles, extracting 5–10% more usable capacity from LiSOCl₂ cells in low-power applications.

7.3 Sustainable Materials

Research into cobalt-free cathodes and biodegradable casings aims to reduce the environmental impact of lithium batteries without compromising performance.

8. Comparative Selection Guide

Longest lifespan | ER34615 | 19,000mAh capacity supports high-drain applications for 15+ years. |

Smallest footprint | SPC1520 | 26mm × 15.2mm profile fits medical implants and RFID tags. |

Lowest cost per Wh | ER26500 | Balances capacity (8,500mAh) and cost for high-volume IoT deployments. |

Highest temperature tolerance | ER34615 (with high-temp electrolyte) | Special formulations operate up to 125°C for industrial sensors. |

Cold-weather performance | ER17505 | Maintains 80% capacity at -40°C for Arctic applications. |

9. Conclusion

The 3.6V LiSOCl₂ battery family, encompassing models like ER26500, SPC1550, SPC1520, ER14250, ER14505, ER17505, ER18505, and ER34615, offers unparalleled versatility for powering the IoT revolution. By understanding their technical nuances, customization potential, and real-world trade-offs, engineers can select the optimal battery for applications ranging from smart meters to deep-sea exploration.